1 Kukonzekera musanayesedwe

1) Choyesera kuuma ndi indenter chomwe chimagwiritsidwa ntchito poyesa kuuma kwa Vickers chiyenera kutsatira zomwe zili mu GB/T4340.2;

2) Kutentha kwa chipinda nthawi zambiri kuyenera kulamulidwa mkati mwa 10 ~ 35℃. Pa mayeso okhala ndi zofunikira kwambiri, ayenera kulamulidwa pa (23±5)℃.

Zitsanzo ziwiri

1) Pamwamba pa chitsanzocho payenera kukhala pathyathyathya komanso posalala. Ndikofunikira kuti pamwamba pa chitsanzocho pakhale poyera kuti pakhale poyera: Mtengo wapamwamba wa roughness parameter: Vickers hardness sampuli 0.4 (Ra)/μm; small load Vickers hardness sampuli 0.2 (Ra)/μm; micro Vickers hardness sampuli 0.1 (Ra)/μm

2) Pa zitsanzo za Vickers ndi micro Vickers zolemera pang'ono, tikukulimbikitsani kusankha kupukuta koyenera ndi kupukuta kwa electrolytic kuti mugwiritse ntchito pamwamba pake malinga ndi mtundu wa zinthu.

3) Kukhuthala kwa chitsanzo kapena gawo loyesera kuyenera kukhala kochepera 1.5 kuposa kutalika kwa diagonal kwa indentation

4) Mukagwiritsa ntchito katundu wochepa ndi ma micro Vickers poyesa, ngati chitsanzocho ndi chaching'ono kwambiri kapena chosakhazikika, chitsanzocho chiyenera kuyikidwa mkati kapena kulumikizidwa ndi chogwirira chapadera musanayese.

3Njira yoyesera

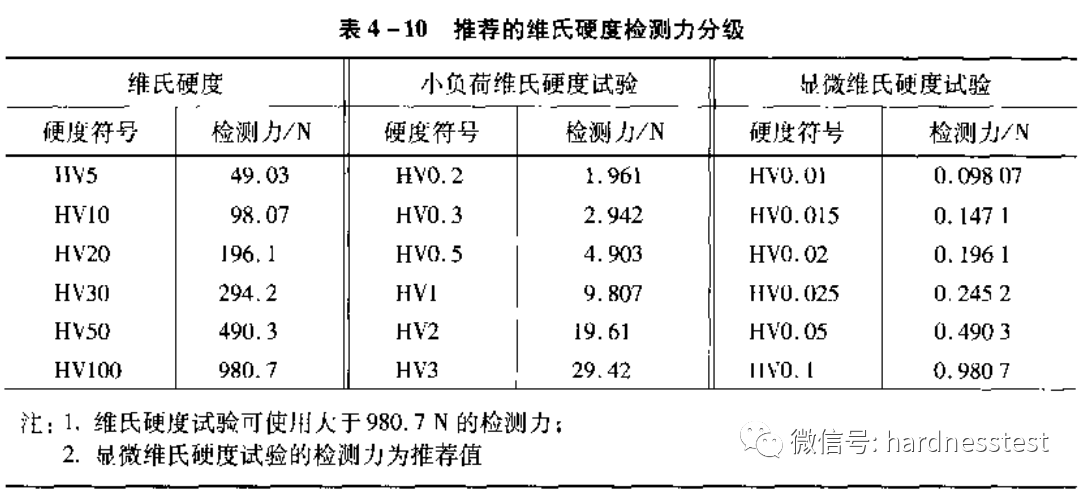

1) Kusankha mphamvu yoyesera: Malinga ndi kuuma, makulidwe, kukula, ndi zina zotero za chitsanzo, mphamvu yoyesera yomwe yawonetsedwa mu Table 4-10 iyenera kusankhidwa kuti igwiritsidwe ntchito poyesa.

2) Nthawi yogwiritsira ntchito mphamvu yoyesera: Nthawi kuyambira pachiyambi cha kugwiritsa ntchito mphamvu mpaka kumaliza ntchito yonse ya mphamvu yoyesera iyenera kukhala mkati mwa masekondi 2 mpaka 10. Pa mayeso ang'onoang'ono a Vickers ndi micro Vickers hardness, liwiro lotsika la indenter siliyenera kupitirira 0.2 mm/s. Nthawi yogwiritsira ntchito mphamvu yoyesera ndi masekondi 10 mpaka 15. Pazinthu zofewa kwambiri, nthawi yogwiritsira ntchito ikhoza kukulitsidwa, koma cholakwikacho chiyenera kukhala mkati mwa masekondi 2.

3) Mtunda kuchokera pakati pa mzere wozungulira mpaka m'mphepete mwa chitsanzo: Zitsulo, mkuwa ndi zitsulo zamkuwa ziyenera kukhala zochepera nthawi 2.5 kutalika kwa mzere wozungulira; zitsulo zopepuka, lead, tin ndi zitsulo zawo ziyenera kukhala zochepera nthawi 3 kutalika kwa mzere wozungulira. Mtunda pakati pa malo awiri ozungulira: pa zitsulo, mkuwa ndi zitsulo zamkuwa, ziyenera kukhala zochepera nthawi 3 kutalika kwa mzere wozungulira wa chizindikiro choyimitsa; pa zitsulo zopepuka, lead, tin ndi zitsulo zawo, ziyenera kukhala zochepera nthawi 6 kutalika kwa mzere wozungulira wa mzere wozungulira.

4) Yesani kuchuluka kwa mawerengedwe a kutalika kwa ma diagonal awiri a indentation, ndikupeza kuchuluka kwa kuuma kwa Vickers malinga ndi tebulo, kapena kuwerengera kuchuluka kwa kuuma malinga ndi fomula.

Kusiyana kwa kutalika kwa ma diagonal awiri a indentation pa ndege sikuyenera kupitirira 5% ya mtengo wapakati wa ma diagonal. Ngati kupitirira, kuyenera kulembedwa mu lipoti la mayeso.

5) Mukayesa pa chitsanzo cha pamwamba chopindika, zotsatira zake ziyenera kukonzedwa malinga ndi tebulo.

6) Kawirikawiri, tikulimbikitsa kunena za mayeso a kuuma kwa mfundo zitatu pa chitsanzo chilichonse.

4 Gulu la Vickers hardness tester

Pali mitundu iwiri ya zoyesera zolimba za Vickers zomwe zimagwiritsidwa ntchito kwambiri. Izi ndi chiyambi cha momwe zoyesera zolimba za Vickers zimagwiritsidwira ntchito kwambiri:

1. Mtundu wa muyeso wa diso;

2. Mtundu wa muyeso wa mapulogalamu

Gulu 1: Mtundu wa muyeso wa diso Makhalidwe: Gwiritsani ntchito diso poyesa. Kagwiritsidwe Ntchito: Makinawa amapanga (diamondi ◆) indentation, ndipo kutalika kwa diamondi kumayesedwa ndi diso kuti apeze kuuma kwake.

Gulu 2: Mtundu wa muyeso wa mapulogalamu: Makhalidwe: Gwiritsani ntchito pulogalamu yolimba poyesa; yosavuta komanso yosavuta pa maso; imatha kuyeza kuuma, kutalika, kusunga zithunzi zopindika, malipoti a nkhani, ndi zina zotero. Kagwiritsidwe Ntchito: Makinawa amapanga (diamondi ◆) kupindika, ndipo kamera ya digito imasonkhanitsa kupindika pa kompyuta, ndipo kuuma kumayesedwa pa kompyuta.

5Kugawa mapulogalamu: Mabaibulo 4 oyambira, mtundu wodzilamulira wa turret wokha, mtundu wodziyimira wokha, komanso mtundu wodziyimira wokha.

1. Mtundu woyambira

Imatha kuyeza kuuma, kutalika, kusunga zithunzi zopindika, malipoti a nkhani, ndi zina zotero;

2. Pulogalamu yowongolera yokha ya turret imatha kulamulira turret yoyesera kuuma, monga, lenzi yolinga, indenter, kukweza, ndi zina zotero;

3. Mtundu wokhazikika wokha wokhala ndi tebulo loyesera la XY lamagetsi, bokosi lolamulira la nsanja ya 2D; Kuwonjezera pa ntchito yokhazikika ya turret, pulogalamuyo imathanso kukhazikitsa malo ndi mfundo, madontho okhazikika, muyeso wokha, ndi zina zotero;

4. Mtundu wodziyimira wokha wokhala ndi tebulo loyesera lamagetsi la XY, bokosi lowongolera nsanja ya 3D, kuyang'ana kwa Z-axis; Kuwonjezera pa ntchito yodziyimira yokha, pulogalamuyo ilinso ndi ntchito yoyang'ana kwa Z-axis;

6Momwe mungasankhire choyesera kuuma kwa Vickers choyenera

Mtengo wa choyezera kuuma kwa Vickers umasiyana malinga ndi kasinthidwe ndi ntchito yake.

1. Ngati mukufuna kusankha yotsika mtengo kwambiri, ndiye kuti mungasankhe:

Zipangizo zokhala ndi chophimba chaching'ono cha LCD ndi cholowera chozungulira chamanja kudzera mu eyepiece;

2. Ngati mukufuna kusankha chipangizo chotsika mtengo, ndiye kuti mungasankhe:

Zipangizo zokhala ndi chophimba chachikulu cha LCD, chowonera maso chokhala ndi cholembera cha digito, ndi chosindikizira chomangidwa mkati;

3. Ngati mukufuna chipangizo chapamwamba kwambiri, mungasankhe:

Zipangizo zokhala ndi chophimba chokhudza, sensa yotsekedwa, chowonera maso chokhala ndi chosindikizira (kapena USB flash drive), screw yokweza giya la nyongolotsi, ndi cholembera cha digito;

4. Ngati mukuganiza kuti n'kotopetsa kuyeza ndi diso, ndiye kuti mungasankhe:

Muli ndi makina oyezera zithunzi zolimba a CCD, muyeze pa kompyuta popanda kuyang'ana diso, lomwe ndi losavuta, losavuta kumva, komanso lachangu. Muthanso kupanga malipoti ndikusunga zithunzi zopindika, ndi zina zotero.

5. Ngati mukufuna ntchito yosavuta komanso yodziyimira yokha, ndiye kuti mungasankhe:

Choyesa kuuma kwa Vickers chokha komanso choyesa kuuma kwa Vickers chokha chokha

Zinthu: khazikitsani malo ndi chiwerengero cha mfundo, muzizilemba zokha komanso mosalekeza, ndikuziyeza zokha.

Nthawi yotumizira: Okutobala-17-2024