Pali mitundu yambiri ya zokutira zachitsulo. Zophimba zosiyanasiyana zimafuna mphamvu zosiyanasiyana zoyesera poyesa kuuma kwa microhardness, ndipo mphamvu zoyesera sizingagwiritsidwe ntchito mwachisawawa. M'malo mwake, mayeso ayenera kuchitidwa motsatira miyezo ya mphamvu yoyesera yomwe ikuperekedwa ndi miyezo. Lero, makamaka tiyambitsa mayeso a micro Vickers a zinc coatings kapena zinc-aluminium-magnesium alloy coatings zomwe zimagwiritsidwa ntchito pachitsulo.

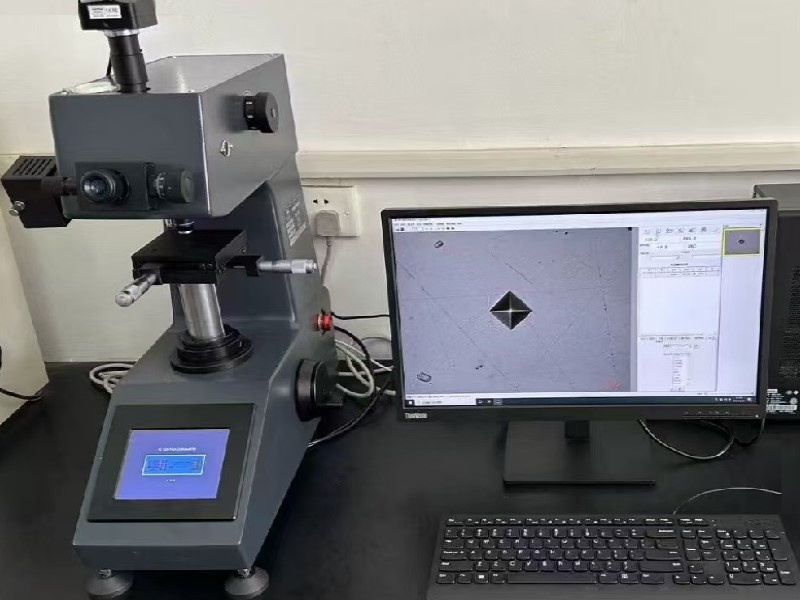

1. Kukonzekera zitsanzo zapamwamba za metallographic za zokutira za zinc (kapena zokutira za aluminiyamu-magnesium) ndi gawo loyamba poyesa zokutira. Kukonzekera zitsanzo za zokutira za zinc kumaphatikizapo magawo angapo, kuphatikizapo kutengera zitsanzo, kuziyika, ndi kupukuta kale. Cholinga chokonzekera zitsanzo zotere ndikupukuta pamwamba pa workpiece kukhala malo osalala, athyathyathya omwe amalola kuwona bwino ma indentations a Vickers, zomwe zimathandiza kuyeza molondola miyeso ya indentations kuti mupeze kuuma.

2. Poyesa kuuma kwa zinc coatings: popeza zinc coatings ndi zokhuthala pang'ono, mayeso a kuuma akhoza kuchitidwa ndi mphamvu zosiyanasiyana zoyesera. Pa chitsanzo chomwecho, mphamvu yoyesera ikagwiritsidwa ntchito yaying'ono, kukula kwa indenti kumakhala kochepa; Mosiyana ndi zimenezi, mphamvu yoyesera ikakula, kukula kwa indenti kumakhala kwakukulu. Ngati chophimba chozungulira indenti chikuwonetsa zizindikiro za kusweka kapena kusinthika, mphamvu yoyesera yochepa iyenera kusankhidwa. Njirayi imabwerezedwanso mpaka chophimba chozungulira indenti ya Vickers chikhalebe bwino popanda kusinthika—mlingo wa mphamvu yoyesera uwu ndi woyenera pa chitsanzocho.

2.1 Makulidwe osiyanasiyana a kuvala amagwirizana ndi magulu enaake a mphamvu yoyesera, zomwe ndizofunikira kwambiri popewa kusokoneza zotsatira za mayeso. Izi ndi zomwe zingagwiritsidwe ntchito posankha mphamvu yoyesera ya kuvala kofala (zinc plating, chromium plating), komwe kumagwiritsidwa ntchito kwa oyesa kuuma kwa micro Vickers (HV):

| Mtundu Wokutira | Kuphimba Kukhuthala (μm) | Malangizo Mphamvu Yoyesera (gf) | Zofanana Mulingo wa HV | Malangizo Ofunika Opewera |

| Zinki Kuphimba | 5 ~ 15 | 25 ~ 50 | HV0.025, HV0.05 | Zinc plating ndi yofewa (nthawi zambiri HV50 ~ 150); mphamvu yochepa imaletsa kupindika kwambiri. |

| Zinki Kuphimba | 15 ~ 50 | 50 ~ 100 | HV0.05, HV0.1 | Pamene makulidwe akuwonjezeka, mphamvu imatha kukwezedwa moyenera kuti zitsimikizire kuti m'mbali mwake muli bwino. |

| Chromium Kuphimba | 1 ~ 5 | 10 ~ 25 | HV0.01, HV0.025 | Chromium yolimba (HV800~1200) ili ndi kulimba kwakukulu; mphamvu yochepa imaletsa kuwonongeka kwa indenter. |

| Chromium Kuphimba | 5 ~ 20 | 25 ~ 100 | HV0.025, HV0.1 | Pamene makulidwe >10μm, HV0.1force imalinganiza kulondola ndi kugwira ntchito bwino. |

| Chosakaniza Kuphimba | <5 | ≤25 | HV0.01, HV0.025 | Pa zophimba monga zinc-nickel alloy ndi chromium-nickel alloy, lekani kuti kupindika kwa madzi kusalowe mu zophimbazo. |

2.2 Zinthu Zina Zofunika Kwambiri Zokhudza Kusakhazikika kwa Maganizo

Kuwonjezera pa makulidwe, zinthu ziwiri zotsatirazi zidzasintha kwambiri kusankha mphamvu yoyesera, ndipo ziyenera kuweruzidwa potengera zochitika zenizeni:

Kuphimba Kuuma kwa Mitundu:

Zophimba zofewa (monga zinc plating, HV <200): Ngati mphamvu yoyesera ndi yaying'ono kwambiri, ma indentations amatha kusokonekera chifukwa cha kusintha kwa pulasitiki kwa chophimbacho. Ndikofunikira kusankha malire apamwamba a mtundu womwe ukulangizidwa (monga., makulidwe 10 μm, sankhani mphamvu yoyesera ya 50gf).

Zophimba zolimba (monga chromium plating, HV > 800): Kulimba kwambiri kumabweretsa kupindika pang'ono, kotero mphamvu yoyesera siyenera kukhala yaying'ono kwambiri (monga, makulidwe 5 μm, sankhani mphamvu yoyesera ya 25gf) kuti mupewe cholakwika choyezera cha kupindika kwa kupindika kupitirira ± 5%.

2.3 Zofunikira pa Miyezo ndi Mafotokozedwe

Makampani osiyanasiyana ali ndi miyezo yomveka bwino. Mwachitsanzo:

Makampani opanga magalimoto nthawi zambiri amagwiritsa ntchito ISO 14577 (Instrumented Indentation Test), yomwe imalola kusintha mphamvu malinga ndi makulidwe a chophimbacho;

Makampani ambiri amatanthauza ASTM E384, yomwe imafuna kuti chopingasa cha indentation chikhale ≤ 1/2 ya makulidwe a glaze ndi ≥ nthawi 10 kuposa radius ya indenter nsonga (kuti tipewe zotsatira za nsonga).

Pomaliza, kusankha mphamvu yoyesera poyesa kuuma kwa micro-Vickers kwa zokutira zachitsulo kuyenera kutsatira mfundo yakuti "kukhuthala koyamba, kusintha kuuma, ndi chitsimikizo chokhazikika":

Choyamba, dziwani kuchuluka kwa mphamvu yoyesera kutengera makulidwe a chophimba (onani tebulo pamwambapa);

Sinthani mphamvu malinga ndi kuuma kwa chophimbacho (sankhani malire apamwamba a chophimba chofewa ndi malire otsika a chophimba cholimba);

Pomaliza, tsatirani miyezo yamakampani (monga ISO 14577 ndi ASTM E384) kuti muwonetsetse kuti zotsatira za mayeso ndi zoona.

Nthawi yotumizira: Sep-03-2025