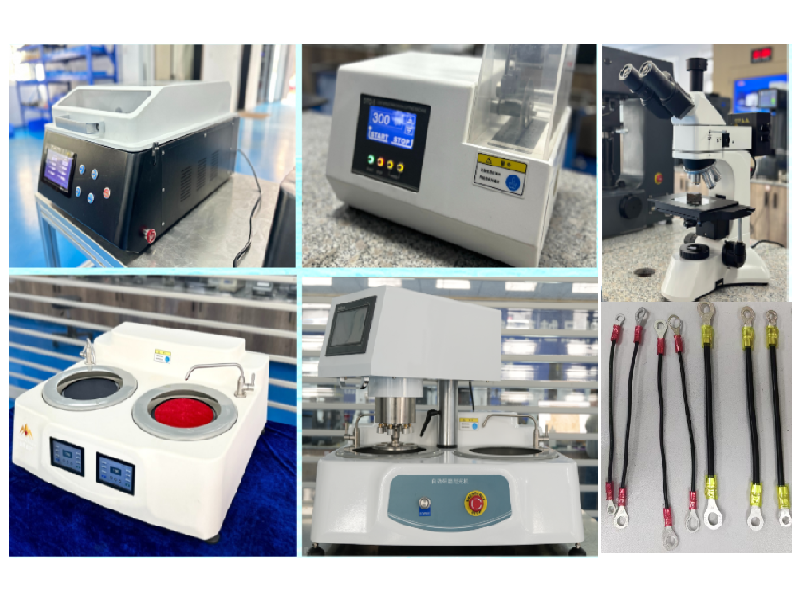

Muyezo umafuna ngati mawonekedwe a crimping a terminal yolumikizira ali oyenerera. Kufooka kwa waya wa crimping wa terminal kumatanthauza chiŵerengero cha malo osalumikizidwa apagawo lolumikizira mu malo olumikizirana ndi malo onse, lomwe ndi gawo lofunika kwambiri lomwe limakhudza chitetezo ndi kudalirika kwa malo olumikizirana. Kuchuluka kwa porosity kungayambitse kukhudzana koyipa, kuwonjezera kukana ndi kutentha, motero kukhudza kukhazikika ndi chitetezo cha kulumikizana kwamagetsi. Chifukwa chake, zida zaukadaulo zowunikira metallographic zimafunikira kuti zizindikire ndi kusanthula porosity pamwamba. Kudula zitsanzo za metallographic, makina opukutira ndi kupukuta zitsanzo za metallographic, ndi microscope ya metallographic ndizofunikira kuti ziyese ndikukonzekera malo olumikizirana, kenako kujambula zithunzi kumasanthulidwa ndi pulogalamu ya microscope ya metallographic kuti iwunike magawo onse.

Njira yokonzekera zitsanzo: Chitsanzo chomwe chiyenera kuonedwa (nthiti zolimbitsa za terminal ziyenera kupewedwa) chimadulidwa ndikuyesedwa ndi makina odulira zitsanzo a metallographic - tikulimbikitsidwa kugwiritsa ntchito makina odulira molondola podula, ndipo chogwirira ntchito chomwe chapezedwa chimayikidwa mu chitsanzo chokhala ndi nsanja ziwiri pogwiritsa ntchito makina odulira zitsulo, kenako malo owunikira ophatikizidwa amafunika kuphwanyidwa ndikupukutidwa pamalo agalasi ndi chopukusira zitsulo ndikupukutidwa, kenako ndikuzimiririka ndi mankhwala ndikuyikidwa pansi pa maikulosikopu ya zitsulo kuti ziwunikiridwe ndikuwunikidwa.

Nthawi yotumizira: Marichi-28-2025