Maikulosikopu Yowongoka Yopangidwa ndi Zitsulo ya LHMICV5100 Yodziyimira Yokha Yokha

Ntchito zonse zimapangidwa motsatira mfundo za ergonomic kuti zichepetse kutopa kwa wogwiritsa ntchito. Kapangidwe kake ka modular component kamalola kuphatikiza kosinthasintha kwa ntchito za dongosolo. Ikuphatikizapo ntchito zosiyanasiyana zowonera, kuphatikiza bright-field, dark-field, oblique illumination, polarized light, ndi DIC differential interferometry, ndi ntchito zomwe zingasankhidwe kutengera ntchito zinazake.

Imathandizira mawonekedwe owoneka bwino kwambiri a 25mm padziko lonse lapansi, zomwe zimakubweretserani mawonekedwe atsopano owonera bwino. Kusintha kwa diopter kosiyanasiyana kumatha kukwaniritsa zosowa za ogwiritsa ntchito ambiri pa mapulogalamu enaake.

Zolinga za semi-apochromatic za bright-field ndi dark-field zimapangidwa ndi magalasi osankhidwa mosamala kwambiri komanso ukadaulo wapamwamba wokutira kuti abwereze mitundu yachilengedwe ya chitsanzocho; kapangidwe ka semi-apochromatic kali ndi magwiridwe antchito abwino kwambiri okonzanso mitundu, zomwe zimapangitsa kuti chithunzicho chikhale chosiyana komanso chomveka bwino.

Dongosolo la polarization limaphatikizapo polarizer insert ndi analyzer insert, zomwe zimatha kuzindikira kuwala kwa polarized. Mu semiconductor ndi PCB inspection, imatha kuchotsa kuwala kosochera ndikupangitsa tsatanetsatane kukhala womveka bwino.

Chowunikira chozungulira cha 360° chimalola kuti muwone mosavuta mawonekedwe a chitsanzocho pansi pa kuwala ndi ma angles osiyanasiyana a polarization popanda kusuntha chitsanzocho.

● Gawo la XY lopangidwa ndi injini yolondola kwambiri, lophatikizidwa ndi makina owongolera otsekedwa, limalola kusanthula chithunzi chachikulu komanso kupanga zithunzi zogwira ntchito bwino, kuonetsetsa kuti magawo ambiri azithunzi aphatikizidwa bwino.

● Imathandizira njira zojambulira zomwe zakonzedwa, imasintha kuti igwirizane ndi zitsanzo zosakhazikika, komanso imawonjezera kupambana kwa ma splicing pamalo ovuta.

●Z-axis imayendetsedwa ndi magetsi, zomwe zimathandiza kuti chithunzi chiziyang'ana zokha.

Chokokera kutsogolo kwa chowunikira chimapangitsa kusinthana pakati pa minda yowala ndi yamdima kukhala kosavuta ndipo chili ndi ntchito yolumikizira fyuluta ya neutral density. Izi zimalepheretsa maso a wogwiritsa ntchito kusonkhezeredwa ndi kuwala kwamphamvu akasintha kuchoka ku minda yamdima kupita ku minda yowala, zomwe zimapangitsa kuti wogwiritsa ntchito azikhala bwino.

Chosinthira cha multi-aperture cholinga chimalola kuti pakhale kuwunikira koyenera komanso kosalekeza pakukula kochepa, kwapakati, komanso kwakukulu kwa chitsanzo chomwecho pamalo osiyanasiyana owonera.

| Dongosolo la kuwala | Dongosolo la kuwala lokonzedwa bwino |

| Chitoliro chowonera | Kupendekeka kwa 30°, chubu chowonera cha njira zitatu chopanda malire, kusintha mtunda pakati pa anapiye: 50mm ~ 76mm, chiŵerengero chogawanika cha beam cha magawo awiri, binocular: trino = 100:0 kapena 0:100 |

| chojambula cha maso | Maso okwera, mawonekedwe otseguka a PL10X / 25mm, diopter yosinthika. |

| Minda yowala ndi yamdimaLenzi yolunjika pang'ono | LMPLFL 5X /0.15 BD DIC WD13.5mmLMPLFL10X/0.30 BD DIC WD9.0mmLMPLFL20X/0.5 BD DIC WD2.5mmLMPLFL50X/0.80 BD WD1.0mmLMPLFL100X / 0.90 BD WD 1.0mm |

| chosinthira | Chosinthira cha mabowo 6 cha minda yowala ndi yamdima, yokhala ndi malo a DIC |

| chimango | Kamera ili ndi chimango chowunikira komanso njira yotsika yowunikira bwino ya coaxial komanso yowunikira bwino. Ulendo wowongolera bwino ndi 25mm, ndipo kulondola kwa kusintha bwino ndi 0.001mm. Ikuphatikizapo chipangizo choletsa kutsetsereka komanso switch ya upper limit yosasinthika. |

| Dongosolo la kuunikira | Chowunikira chowala ndi chakuda chokhala ndi diaphragm yotseguka mosinthasintha, diaphragm yamunda, ndi chosinthika pakati; chokhala ndi chipangizo chosinthira chowunikira cha kuwala ndi chakuda; chokhala ndi malo osefera utoto ndi malo oyezera polarizer/analyzer. |

| chipinda cha nyale | Chipinda cha nyali cha 12V 100W halogen, choyenera kutumizidwa ndi kuwunikira, chikupezeka kuti mugule pasadakhale. |

| Z-axis | Kuyang'ana Mwachangu |

| Nsanja yamagetsi | Ulendo wa pa pulatifomu: Njira yolunjika * Njira yolunjika = 80 * 60 (gawo: mm)Chowongolera chowongolera: 2000μmKulondola kwa kubwerezabwereza kwa XY: mkati mwa ± 2 μmKubwerezabwereza kwa Z-axis: mkati mwa ± 1 μmChisankho pa magawo 16: 0.625μm pa sitepe iliyonse Ngodya ya sitepe ya mota ya stepper: 1.8° Mphamvu yogwira ntchito yovotera: 1.0A pa shaft iliyonse (yoyendetsedwa ndi 24V) Kulemera kwakukulu: ≥5kg Chilolezo chachikulu choyendera ndi kubwerera: 2 micrometers Kutalika kwakukulu kwa chitsanzo ndi 25mm (kutalika kwina kumatha kusinthidwa). |

| Bokosi lowongolera dalaivala | Imagwiritsa ntchito doko lodziwika bwino la RS232 kuti ilumikizane ndi PC (115200 baud rate).Kuwongolera madoko otsatizana kumalola kukhazikitsa liwiro la injini, mtunda, ndi komwe ikupita. |

| Zomangira zina | Choyikapo cha Polarizer, choyikapo cha analyzer chozungulira cha 360°, ndi choyikapo cha fyuluta yosokoneza kuti chiziwunikira. |

| Dongosolo Losanthula | Pulogalamu yowunikira metallographic yeniyeni ya FMIA 2025 ndi pulogalamu yowunikira ma porosity |

| chipangizo cha kamera | Ma megapixels 5, 36 fps |

| Mawonekedwe a lenzi ya adapter ya 0.5X, micrometer | |

| Makompyuta owongolera mafakitale | Intel i5 purosesa, 64GB RAM, 1TB SSD, 27-inch 4K monitor |

Pulogalamu yathu yowunikira zithunzi za metallographic ndi njira yatsopano yopangidwa ndi kampani yathu kutengera zosowa za mayeso a metallographic a makampani opanga zinthu, makampani opanga zida zamagalimoto, makampani othandizira kutentha, makampani opanga zitsulo, makampani opanga zida zamagetsi, makampani opanga zida zama sitima, ndi makampani osiyanasiyana oyesera. Pofuna kukweza kuchuluka kwa ziyeneretso za malonda ndikuthandizira kukweza mulingo woyesera wa ma laboratories osiyanasiyana, tinasonkhanitsa zosowa ndi malingaliro a akatswiri ndi aphunzitsi ochokera m'mafakitale osiyanasiyana.

Pulogalamu yowunikira zithunzi za metallographic yasinthidwanso ndi kusinthidwa kwathunthu. Dongosololi limaphimba miyezo yambiri yoyesera metallographic yapadziko lonse lapansi komanso yapadziko lonse lapansi, limaphatikiza kusanthula kwa kuchuluka ndi kwabwino, ndipo limawonjezera kapangidwe ka kuzama kwa munda ndi ntchito zosokera zithunzi. Mawonekedwe ake ndi osavuta ndipo amatha kujambula zithunzi zamitundu yambiri kuti zikonzedwe ndi kusanthula zithunzi pakati. Ntchitoyi ndi yosavuta, kuchotsa njira zosiyanasiyana zovuta za pulogalamu yam'mbuyomu, zomwe zimapangitsa kuti kuyesako kukhale kofulumira komanso kogwira mtima.

Tapanga njira yatsopano yowunikira metallographic "yaukadaulo, yolondola, komanso yothandiza" kuti tichepetse kusanthula metallographic.

Laibulale yadziko lonse ya dongosolo la mapulogalamu ili ndi magulu mazana ambiri, makamaka okhudza miyezo ya metallographic yomwe imagwiritsidwa ntchito kwambiri komanso kukwaniritsa zofunikira pa kusanthula ndi kuyesa metallographic kwa mabungwe ambiri. Magulu oyenera amatchulidwa ndikutsegulidwa malinga ndi zosowa za mafakitale osiyanasiyana kuti akwaniritse zofunikira pa kuyesa kwa makampani. Ma module onse amapezeka kwaulere kwa moyo wonse, ndipo miyezo imakwezedwa kwaulere kwa moyo wonse.

Popeza kuchuluka kwa zinthu zatsopano ndi magiredi otumizidwa kunja kukuchulukirachulukira, zinthu ndi miyezo yowunikira yomwe sinaphatikizidwebe mu pulogalamuyo ikhoza kusinthidwa ndikulowetsedwa padera.

Ubwino ndi ntchito zakepulogalamu yowunikira metallographic:

- Kujambula ndi kupeza zithunzi za kanema: Kujambula zithunzi za batch, kutchula mayina a batch, kusunga zithunzi za batch, kusindikiza zithunzi za batch ndi kukula kokhazikika ndi ntchito zina zogwiritsira ntchito zithunzi zambiri zimapangitsa kuti njira yowunikira zitsanzo za batch ikhale yosavuta komanso yothandiza.

- Zapamwambamakonda a kamera:Nthawi yowonekera, kuwonjezeka, kuthwanima, kuchuluka, gamma, kusiyana, kuwala, kuyera bwino, kuyera bwino, ndi zina zomwe zingagwiritsidwe ntchito.

- Dinani kamodziKulinganiza zolinga zonse:Ntchito yowerengera yasinthidwa kwathunthu, zomwe zimakupatsani mwayi womaliza kuwerengera magawo onse ofunikira ndikudina kamodzi. Poyerekeza ndi njira yoyambirira yowerengera, njira yatsopano yowerengera ndi yosavuta komanso yachangu kugwiritsa ntchito.

- Ntchito zokonza zithunzi:kulekanitsa mitundu, kusintha kwa imvi, kuchepetsa, kugawa pakati, kukulitsa chithunzi, kusintha kwa gawo, kukulitsa, kukanda ndi kuchotsa matope, histogram ya chithunzi, ndi zina zotero.

- Chithunzi chokulitsa zotsatira:Zinthu zina zimaphatikizapo kusindikiza zithunzi zambiri, mayina azithunzi, makonda a scale parameter, kutumiza ku PDF/Word/Excel, ndi kuwonetsa chithunzithunzi cha kusindikiza.

Kuyeza ndi kusunga chithunzi:Pali zida zosiyanasiyana zoyezera (kuphatikizapo mtunda, ngodya, ngodya pakati pa mizere iwiri, rectangle, mtunda wa point-to-line, ellipse, polygon, mtunda wa parallel line, arc ya three-point arc, three-point circle, etc.), zomwe zimathandiza kujambula mivi, kulemba zilembo, ndi kuwonjezera... Pali zosankha zingapo zomwe zikupezeka pa mizere yothandizira, m'lifupi mwa mzere, ndi mayunitsi a kutalika; mtundu wa zilembo zoyezera, kukula, ndi kalembedwe ka zilembo ziliponso; deta yoyesera ikhoza kufotokozedwa mwachidule ndikutumizidwa ku Excel.

Ntchito yosanthula bungwe:Laibulale ya mapulogalamu ili ndi mitundu yosiyanasiyana ya miyezo yoyesera, kuphatikizapo GB/ASTM/ISO/DIN/QC/JB/DL/TB/SS ndi miyezo ina yowunikira mabungwe. Miyezo mu laibulale ya mapulogalamu imatha kukwezedwa kwaulere, ndipo pulogalamuyo ili ndi luso lowunikira lokha komanso loyerekeza. Ili ndi ntchito zitatu zowunikira metallographic: yoyamba, yachiwiri, ndi yothandizidwa. Ndi yosavuta, yosavuta, komanso yachangu kugwiritsa ntchito, ndipo imapereka miyeso yolondola komanso yodalirika.

Zinthu zapamwamba zosintha:Kuwongolera siteji pogwiritsa ntchito maikulosikopu yopangidwa ndi injini, kuyika chithunzi mozungulira, kupanga mapu a kuwala kwa 3D, malo osungira zithunzi, ndi zina zotero.

Ma tempuleti osiyanasiyana a malipoti:Imapanga zokha malipoti owunikira a metallographic okhala ndi zithunzi zambiri, ndi zosankha zamitundu yosiyanasiyana ya malipoti a gawo limodzi kapena angapo. Ma tempuleti a malipoti amatha kusinthidwa kuti aphatikizepo ma logo a kampani, mayina a kampani, njira zoyesera, ndi zina zambiri. Ma tempuleti a malipoti okonzedwa mwamakonda amapezekanso kuti akwaniritse zosowa zanu.

Ntchito yowunikira minofu yoyendetsedwa ndi AI:Gawo losanthula minofu ya AI lomwe lingasinthidwe limagwiritsa ntchito luntha lochita kupanga kuti limalize kusanthula ndi kuzindikira kapangidwe kake konse, kuzindikira ndi kusanthula kapangidwe kake ka zinthu zokha. Njira yogwirira ntchito ndi yosavuta, kuchepetsa mphamvu ya ogwira ntchito. Kuwongolera magwiridwe antchito a kuyesa zinthu.

Laibulale Yojambula Yokhazikika Yadziko Lonse:Muli zojambula zambirimbiri za dziko lonse zomwe makasitomala angaziphunzire ndi kuzitchula.

Gawo Lophunzitsira la Metallography:Ikuphatikizapo gawo lophunzitsira za metallography kuti makasitomala aphunzire ndikugwiritsa ntchito.

Ntchito Yokulitsa Kuzama kwa EDF:Kwa zitsanzo zomwe sizili zofanana ndipo sizingagwirizane bwino, pulogalamuyo imapereka ntchito yojambula zithunzi ya EDF yozama kwambiri. Mwa kusintha chiwongolero cha dzanja cha Z-axis micro-adjustment focusing cha microscope, tsatanetsatane womveka bwino mu chitsanzocho udzawonjezedwa nthawi zonse ku zenera lowonetsera la EDF lolimba kuti zisinthidwe modabwitsa. Pulogalamuyo imalemba zithunzi zoyera zokha pamlingo wosiyana wa field ndikuziphatikiza kukhala chithunzi choyera.

Ntchito yosokera chithunzi:Kwa makasitomala omwe akufunika kuyang'ana malo owonera akuluakulu, pulogalamuyi imapereka ntchito yosokera zithunzi. Ogwiritsa ntchito amatha kusuntha nsanja ya XY ya maikulosikopu kuti akwaniritse kusanthula kwakukulu kwa zithunzi ndi kupanga zithunzi bwino kuti atsimikizire kulumikizana bwino kwa malo osiyanasiyana owonera. Izi zimakwaniritsa zosowa za kasitomala zojambula zithunzi za malo owonera akuluakulu ndikuthetsa manyazi osakhala ndi mwayi wojambulira zithunzi chifukwa cha malo osakwanira owonera maikulosikopu.

Imathandizira njira zojambulira zomwe zakonzedwa, imasintha kuti igwirizane ndi zitsanzo zosakhazikika, komanso imawonjezera kupambana kwa ma splicing pamalo ovuta.

Z-axis imayendetsedwa ndi magetsi, zomwe zimathandiza kuti chithunzi chiziyang'ana zokha.

| GB/T 10561-2023 Kutsimikiza kwa Zomwe Zili M'zitsulo Zosakhala Zachitsulo | GB/T 34474.1-2017 Kuwunika kwa kapangidwe ka mikanda mu chitsulo |

| Kufufuza kwa GB/T 7216-2023 Metallographic kwa Iron Yotuwa | Muyezo wa DL/T 773-2016 Spheroidization Rating wa Chitsulo cha 12Cr1MoV Chogwiritsidwa Ntchito mu Mafakitale Ogwiritsa Ntchito Mphamvu Yotentha |

| GB / T 26656 - 2023 Kufufuza kwa Metallographic kwa Vermicular Graphite Cast Iron | DL / T 1422 - 2015 18Cr-8Ni Series Austenitic Stainless Steel Boiler Tube Microstructure Aging Rating Standard |

| GB/T 13299-2022 Njira Yowunikira Kapangidwe Kakang'ono ka Chitsulo | GB /T 3489-2015 Ma alloy olimba - Kutsimikiza kwa metallographic kwa porosity ndi kaboni wosaphatikizika |

| Kufufuza kwa GB/T 9441-2021 Metallographic ya Ductile Iron | JB/T 1255-2014 Mikhalidwe Yaukadaulo Yothandizira Kutentha kwa Zitsulo Zokhala ndi Kaboni Yambiri ya Chromium Yopangira Mabearings Ozungulira |

| Kufufuza kwa GB/T 38720-2020 Metallographic kwa Chitsulo Chozimitsidwa cha Kaboni Wapakati ndi Chitsulo Chopangidwa ndi Kaboni Wapakati | GB / T 1299 - Chida ndi Chitsulo cha Die cha 2014 |

| Njira ya GB/T 224-2019 Yodziwira Kuzama kwa Zitsulo Zochotsedwa mu Kabati | GB / T 25744 - 2010 Kuyang'anira Metallographic ya Zitsulo Zotenthedwa, Zozimitsidwa, ndi Zotenthedwa |

| TB/T 2942.2-2018 ZG230-450 Kuyang'anira Metallographic ya Chitsulo Chopangidwa ndi Zitsulo | Kuzindikira kwa GB/T13305-2008 Metallographic kwa kuchuluka kwa dera la α-phase mu chitsulo chosapanga dzimbiri |

| JB/T 5108-2018 Kusanthula kwa Metallographic kwa Mkuwa Wopangidwa ndi Cast | JB/T 9204-2008 Kuyang'anira Metallographic ya Zitsulo Zolimba Zopangira Zinthu |

| GB/T 6394-2017 Njira Yodziwira Kukula kwa Chitsulo Chapakati | GB/T 13320-2007 Zopangira zitsulo, zithunzi zowunikira kapangidwe ka zitsulo ndi njira zowunikira |

| JB/T7946.1-2017 Metallography ya Aluminiyamu Yopangidwa ndi Ma Cast | Muyezo wa DL/T 999-2006 wa Chitsulo Chozungulira cha Spheroidized cha Magetsi |

| JB/T7946.2-2017 Kutentha Kwambiri kwa Aluminiyamu Yopangidwa ndi Silicon Alloys | Malangizo a DL/T 439-2006 a Zomangira Zotentha Kwambiri mu Zomera Zamagetsi Zotentha |

| JB/T7946.3-2017 Cast Aluminiyamu Alloy Pinhole | DL/T 786-2001 Standard for Testing and Rating of Graphitization of Carbon Steel |

| JB/T 7946.4-2017 Metallography ya Aluminiyamu Yopangidwa ndi Ma Cast | Chithunzi cha B/T 1979-2001 Chithunzi cha zolakwika za kapangidwe ka microstructure zocheperako za chitsulo chomangidwa |

| GB / T 34891 - 2017 Rolling Bearings_Makhalidwe Aukadaulo Othandizira Kutentha kwa Zitsulo Zokhala ndi Kaboni Yambiri ya Chromium | DL/T 674-1999 Muyezo wa Pearlite Spheroidization Rating wa Nambala 20 Chitsulo cha Zomera Zamagetsi Zotentha |

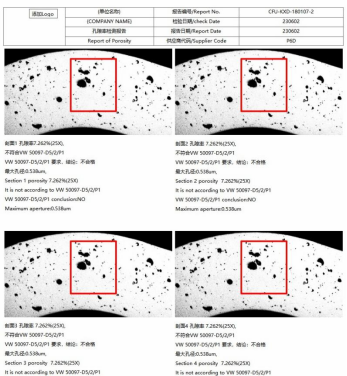

Dongosolo lowunikira zithunzi za porosity la FKX2025 limagwiritsa ntchito kujambula kwa microscopic kuti lizindikire porosity ya ziwalo zamagalimoto. Ndi njira yoyezera porosity ya aluminiyamu yopangidwa ndi chitsulo yomwe imagwiritsidwa ntchito mumakampani opanga magalimoto, mogwirizana ndi miyezo ya Volkswagen ya VW50097 ndi PV6097. Zotsatira zake ndi zolondola komanso zodalirika. Imagwiritsidwa ntchito makamaka pofufuza porosity ya cast porosity ya aluminiyamu ndi cast cast iron castings, komanso ndi yoyenera kusanthula porosity ndi metallographic kusanthula zipangizo zina.

Pulogalamu yowunikira zithunzi za porosity ingagwiritsidwe ntchito ndi gawo lamagetsi kuti ikwaniritse kusanthula kodziyimira payokha, kuyang'ana kokha, kusoka zithunzi zokha, kuyeza porosity yokha, ziwerengero za deta, ndi zotsatira za malipoti.

Ntchito yosokera chithunzi:Ikani magawo osokera ndi mtundu wa chithunzi, dinani "Auto Stitch," ndipo kusoka chithunzicho kudzachitika zokha.

Zokonda za magawo ofufuzira:Mwa kukhazikitsa malo ocheperako, malo ochulukirapo, ndi malire, kufufuza kwathunthu kwa mapu kungathe kuchitika kuti mupeze ma pores onse mkati mwa magawo omwe akhazikitsidwa pamapu onse.

Kusankha chithunzi:Amapereka zida zosankhira monga rectangle, polygon, bwalo, sikweya, ndi katatu. Pambuyo posankha, pulogalamuyo imadzisankhira yokha porosity pamalo osankhidwa.

Kusanthula kwa ma pore:Imatha kusanthula deta monga perimeter, area, major axis, minor axis, equivalent circle diameter, aspect ratio, ndi roundness ya pore iliyonse.

Muyeso wa geometric:Zida zosiyanasiyana zoyezera zingagwiritsidwe ntchito poyesa kukula kwa zinthu

Ziwerengero za deta ndi kupanga malipoti:Imatha kusanthula deta yatsatanetsatane ya magawo a pore iliyonse ndikupanga mitundu iwiri ya malipoti, VW50093 kapena VW50097.