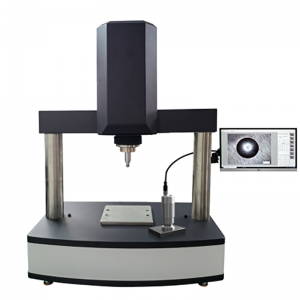

HBST-3000 Chiwonetsero cha digito cha Brinell Hardness Tester chokhala ndi Measuring System & PC

* Kukhudza chophimba cha mtengo wa Kuuma

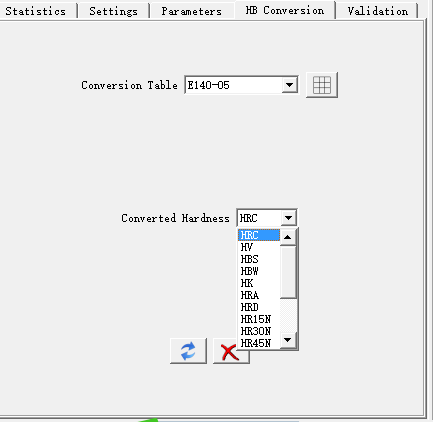

* Kusintha kwa kuuma pakati pa miyeso yosiyanasiyana ya kuuma

* Galimoto yodziyimira payokha, Chidacho chimagwiritsa ntchito mphamvu yoyesera yamagetsi popanda zolemetsa zolemera

* Njira yoyesera yokha, palibe cholakwika chogwirira ntchito cha anthu ;

* Kukhudza Screen ya njira yoyesera, ntchito yosavuta;

* Kulondola kumagwirizana ndi GB/T 231.2, ISO 6506-2 ndi ASTM E10

Mulingo woyezera: 8-650HBW

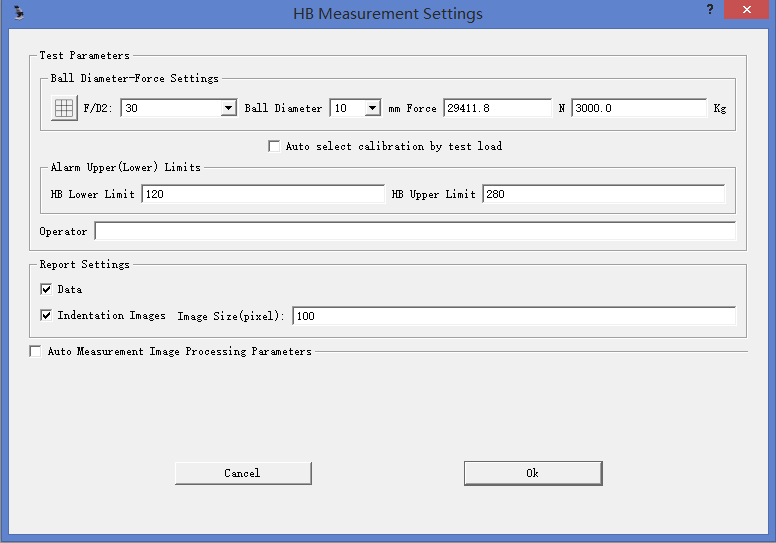

Mphamvu yoyesera: 612.9,980.7,1226,1839, 2452, 4903,7355, 9807, 14710, 29420N (62.5, 100, 125, 187.5, 250, 500, 750, 1000, 1500, 3000kgf)

Kutalika kwakukulu kwa chidutswa choyesera: 280mm

Kuzama kwa mmero: 170mm

Kuwerenga Kuuma: LCD digito yowonetsera

Mtengo Wochepa wa gudumu la ng'oma: 1.25μm

M'mimba mwake mwa mpira wa tungsten carbide: 2.5, 5, 10mm

Nthawi yokhalamo ya mphamvu yoyesera: 0 ~ 60S

Kutulutsa deta: Chosindikizira chomangidwa mkati, RS232/ chimatha kulumikiza kompyuta ku chosindikizira

Kukonza mawu: Excel kapena pepala la Word

Mphamvu: AC 110V/ 220V 60/50HZ

Miyeso:581*269*912mm

Kulemera pafupifupi 135kg

| Gawo lalikulu 1 | Brinell yokhazikika 2 |

| Φ110mm Chitsulo chachikulu chathyathyathya 1 | Chingwe chamagetsi 1 |

| Φ60mm Chitsulo chaching'ono chathyathyathya 1 | Spanner 1 |

| Chitsulo cha Φ60mm V-notch 1 | Satifiketi 1 |

| Cholowera mpira wa Tungsten carbide:Φ2.5, Φ5, Φ10mm, chidutswa chimodzi chilichonse | Buku lothandizira: 1 |

| Chophimba choletsa fumbi 1 | Kompyuta, adaputala ya CCD ndi Mapulogalamu 1 |

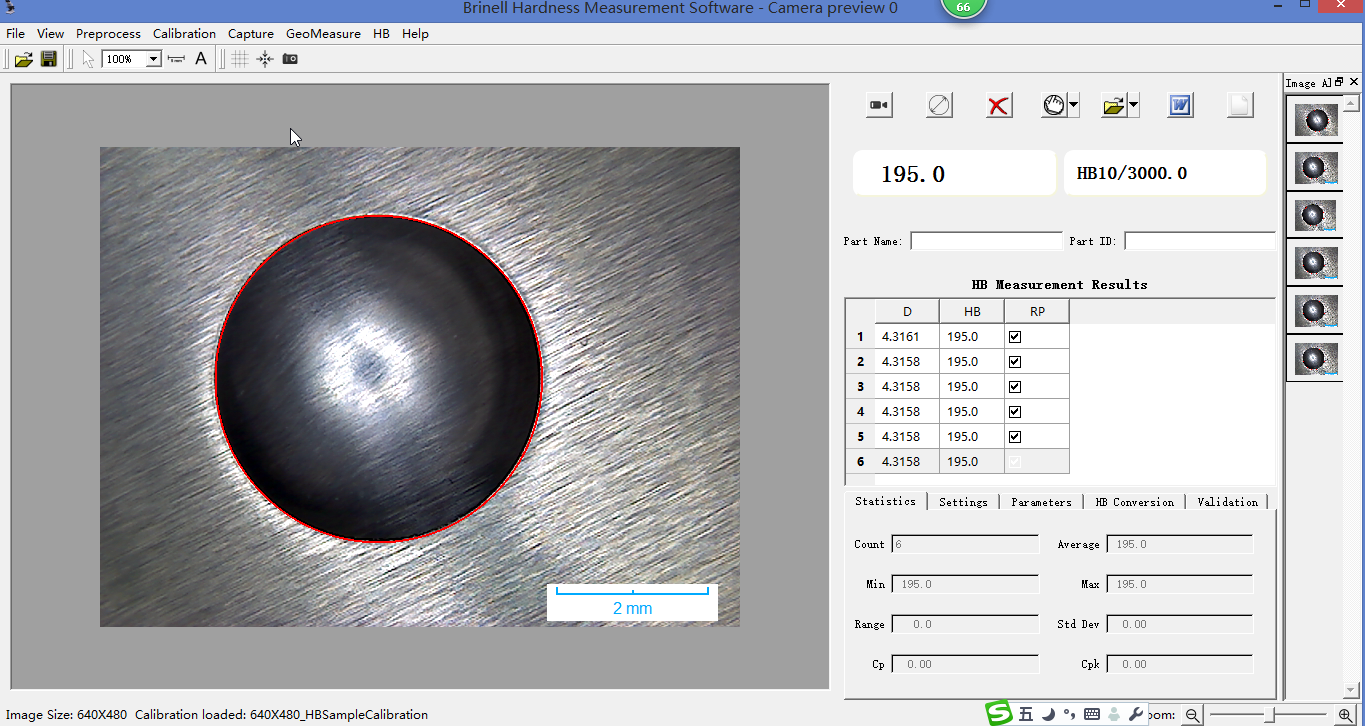

Brinell Kuuma Indentation Makinawa Muyeso System

(Ikhoza kuyikidwa pa choyesera kuuma kapena kugwira ntchito ngati kompyuta yosiyana)

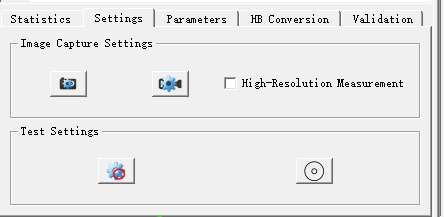

1. Kuyeza kokha: Kujambula kokha mkati mwake ndi kuyeza m'mimba mwake ndikuwerengera kuuma kwa Brinell komwe kukugwirizana nako;

2. Kuyeza ndi manja: Yesani ndi manja indentation, dongosolo limawerengera mtengo wofanana wa Brinell hardness;

3. Kusintha kwa kuuma: Dongosololi likhoza kusintha mtengo woyezedwa wa Brinell hardness HB kukhala mtengo wina wouma monga HV, HR etc;

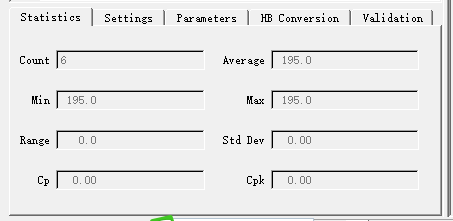

4. Ziwerengero za deta: Dongosololi limatha kuwerengera mtengo wapakati, kusiyana ndi ziwerengero zina za kuuma kwake;

5. Alamu yopitilira muyezo: Imangolemba chizindikiro cha mtengo wosadziwika bwino, pamene kuuma kwake kupitirira mtengo womwe watchulidwa, imangodziwitsa yokha;

6. Lipoti loyesa: Pangani lipoti la WORD lokha, ma tempuleti a lipoti akhoza kusinthidwa ndi wogwiritsa ntchito.

7. Kusunga deta: Deta yoyezera kuphatikizapo chithunzi cholowera mkati ikhoza kusungidwa mu fayilo.

8. Ntchito zina: zimaphatikizapo ntchito zonse za kukonza zithunzi ndi njira yoyezera, monga kujambula zithunzi, kukonza, kukonza zithunzi, muyeso wa geometric, kufotokozera, kasamalidwe ka zithunzi ndi nthawi yosindikizidwa yokhazikika ndi zina zotero.

1. Yosavuta kugwiritsa ntchito: Dinani batani la mawonekedwe kapena dinani batani la kamera kapena dinani batani loti muyambe ntchito yonse yokha; ngati mukufuna kuyeza pamanja kapena kusintha zotsatira, ingokokani mbewa;

2. Kukana phokoso lamphamvu: Ukadaulo wapamwamba komanso wodalirika wozindikira chithunzi ukhoza kuthana ndi kuzindikira kwa indentation pamwamba pa chitsanzo chovuta, mitundu iwiri ya njira yoyezera yokha kuti ithane ndi vuto lalikulu;